How Cassia Glactomannans (Cassia Gum Powder) Effect In Chunks In Jelly Recipes With Carrageenan And Xanthan Gum

Cassia Galactomannans & It’s Features

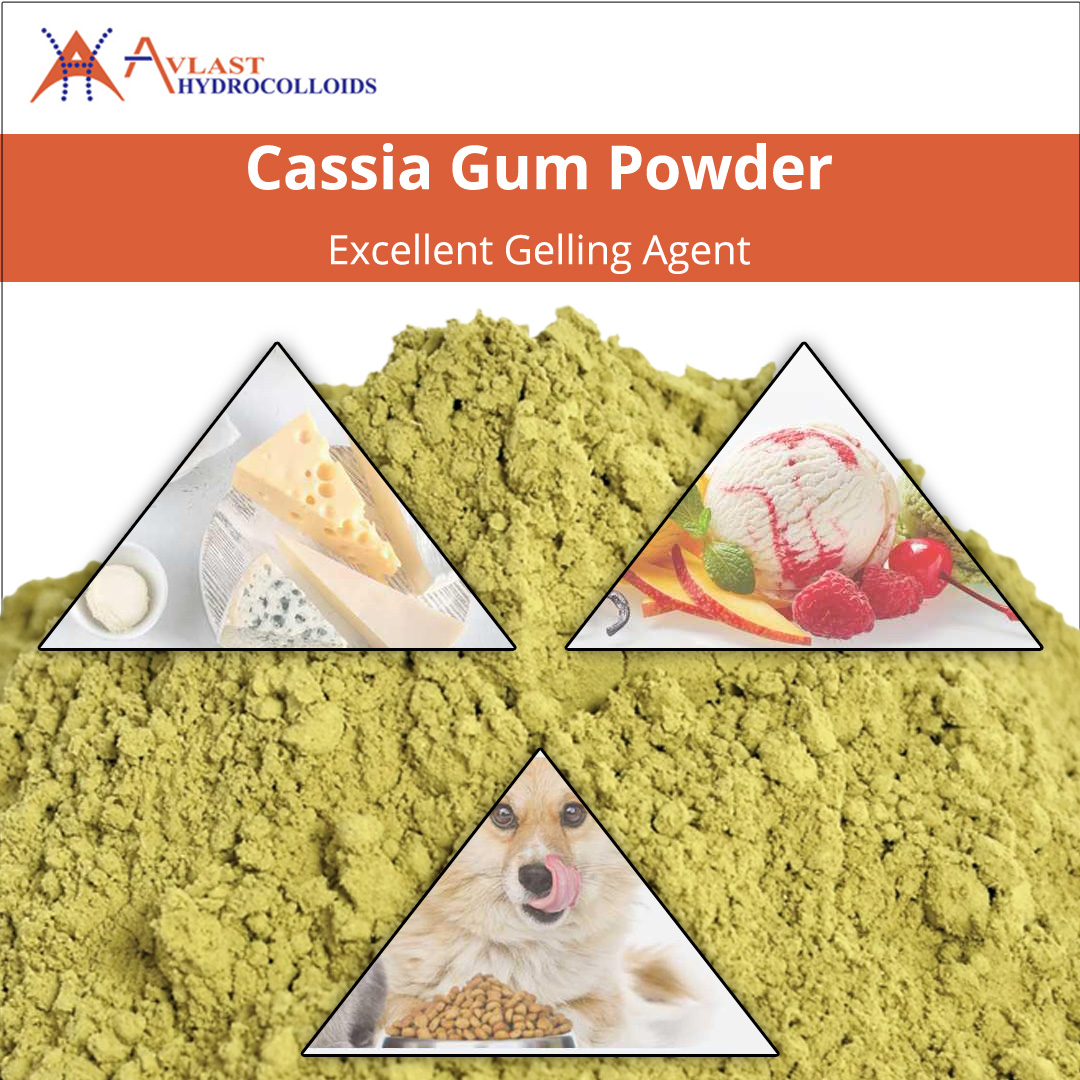

Various galactomannans were blended to make perfect lumps of gels like Carrageenan, Xanthan Gum, Guar Gum, Carob Bean Gum, Cassia Gum Powder, etc. Food formulators can use different hydrocolloids because of unique synergy effect with various other Hydrocolloids. Cassia Gum, Carrageenan and Xanthan Gum hydrocolloids enable formulation and economic benefits by leveraging existing ingredients used in many processed food systems. Some formulators have the ability to improve efficiency and performance attributes and offer the potential for innovative food textures.

The final recipe gel must have a soft texture and without cloudiness, better mouth feeling, and very good chewability.

Physical & Chemical Properties of Cassia Gum

In terms of structure and chemical properties, cassia gum is related to Carob bean gum (Locust Bean Gum), Guar Gum, and Tara Gum. Cassia Gum is a high molecular polysaccharide because of its chain of mannopyranose and galactopyranose units. The ratio of mannose to galactose in these hydrocolloids is 5:1.

The saccharides in these hydrocolloids are of different types and are composed in different amounts such as Galactose is 15.7 – 14.7%, Mannose is 77.2 – 78.9% and glucose is 7.1 – 6.3% Carrageenan is the key ingredient for pet food gels. But Carrageenan price is high compared to Cassia Gum Powder.

Alone Carrageenan gel is soft and also cloudy which shows a pyramid at the bottom of the apparatus. During the milder extraction procedure of carrageenan from algae, the fragments of the algal cell wall of cellulose remain that results in cloudiness.

We need to improve the chunk rigidity, the clearness of gels, and global product quality control in pet food products.

How Cassia Gum is Beneficial in Jelly Recipes?

Due to the excellent retortion stability of Cassia Gum Powder, the hydrocolloid gels of cassia gum are stable even after processing at high-temperature. Cassia Gum gives thermoplastic gels with carrageenan. With an increased quantity of cassia gum, the gel strength of carrageenan solutions is significantly increased with highly efficient means to increase formulation structure at lower hydrocolloid levels.

Xanthan Gums on their own do not have the ability to form gels and Cassia Gum also does not have the ability to form gels. Cohesive elastic gels are formed when aqueous dispersions of hydrocolloids of carrageenan are combined with xanthan gum.

The endproducts contain lower total hydrocolloid levels due to efficient gel formation of cassia gum & carrageenan with Xanthan gum as compared to various other galactomannans.

The galactose and mannose polysaccharide are uniquely branched in cassia gum’s structure.

Due to the various qualities of Cassia Gum, it is more suitable to be used in Jelly Recipes and provide better gelling results.