An Introduction

Cassia Tora seeds (Cassia Tora L., Cassia obtusifolia L., Caesalpiniaceae) undergo various steps of cleaning so that all its impurities like the farm waste and undeveloped seeds and stones are removed when subjected through a mechanical process.

After a thorough cleaning is done, the seeds are de-husked and de-germed by the milling and screening process to get what is called the cassia Tora splits. Subsequently, the splits are ground finely to obtain uniform particles of size.

The Cassia gum powder is known by many names like cassia powder, cassia tora powder, cassia tora splits powder.

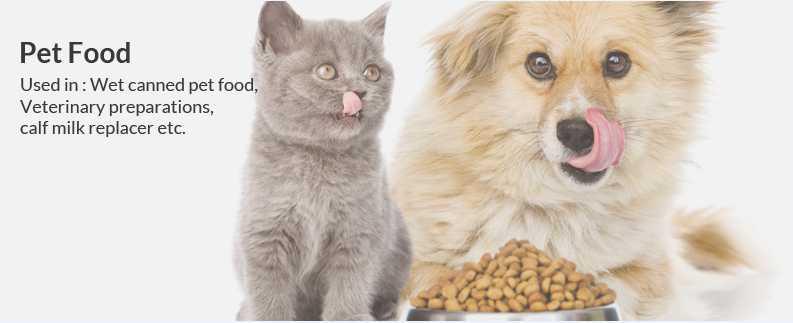

The Cassia Gum Powder E499 finds its application in pet foods while the Cassia Gum Powder E427 is used as a food additive majorly. It is a natural gelling agent and is acclaimed to have extensive industrial uses all over the world.

Cassia Gum Powder Number

| CAS No. of Galactomannan | 11078-30-1 |

|---|---|

| INS No. | 427 |

| EINECS No. | 234-299-6 |

| EEC No. | E499 |

| Australia | AAFCO Approved |

| USA | Approved by FDA, AAFCO for pet food |

Cassia Tora Powder international listings

- United States TSCA

- Australia AICS

- Canada NDSL

- Europe EINECS

- Korea ECL

The GMP certified Cassia gum powder is most often used after combining with the carrageenan and is more suitable than its combination with Locust Bean Gum or Carob Gum. This combination can help prepare air fresheners in the form of gels.

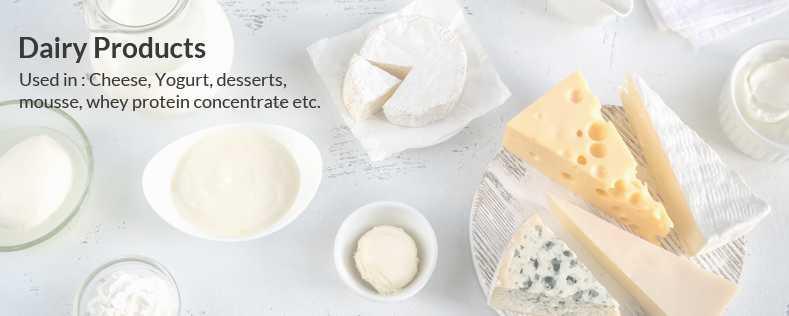

The other important uses include products like mixes, cheese, frozen dairy desserts where it performs the role of thickeners, moisture retention agents, foam stabilizers, emulsifiers, and texturizing agents. Salads, multi-course meat meals, appetizers as well as sandwich ingredients are also known to be prepared with the refined Cassia Gum Powder.

In the field of personal care products due to its property of water solubility and as a surfactant, it is used in the manufacturing of cosmetics, toiletries, and other health care products like topical and non-topical pharmaceuticals, gels, creams, pastes, ointments, and capsules.

Regulatory Information of Cassia Gum

Europe has approved the use of cassia gum under the commission directive EEC No. E499. It is also listed in council directive (70/524/EEC) annex to be used in manufacturing of canned pet food in the form of thickener, stabilizer and also a gelling effect. When used upto the maximum level of 2%, the cassia gum can be recognized as a “GRAS”. Most important uses of cassia gum is in cheese, jellies, baked foods and jams.

Cassia gum is popularly used as food additive in Japan, after the announcement number 160(10/08/1995) by the ministry of health and welfare.

Studies indicate that these structurally related gums lack a toxic effect in animals. This makes it a viable option and to be recognized as safe (GRAS) under its applicability in pet and human foods in the form of thickener.

Abbreviations: FFDCA, Federal Food, Drug, and Cosmetic Act

- PADI - Possible Average Daily Intake

- NTP - National Toxicology Program

- GRAS - Generally Recognized As Safe

- OECD - Organisation for Economic Cooperation and Development

The combination of Cassia Gum and carrageenan can formulate thermoplastic gels with an excellent retorting property that makes them stable and can even increase the strength of the gel. These gums cannot form gels on their own and when combined with Xanthum can form cohesive elastic gels. Due to the unique branched structure of polysaccharide galactose/mannose in refined cassia gum powder as compared to other galactomannans it can form the most efficient gels with Xanthum Gum.

| Gelling Agent | Texturizing Agent |

| Emulsifier | Thickener |

| Stabilizer | Natural Fiber |

| Bonding agent | Moisture retention agent |

Properties of Cassia Gum

The food-grade cassia gum powder is high in molecular weight which is (approx. 200,000-300,000) polysaccharide that consists primarily of a linear chain of 1, 4-β-D-mannopyranose units and 1, 6 linked α-D-galactopyranose units. With a ratio of 5:1 of mannose to galactose, it is similar to the carob bean gum, tara gum, and guar gum from the context of their chemical properties and structures.

Cassia Gum Chemical Structure

Synergistic properties with Carrageenan or Xanthan Gum

When combined with carrageenan it can form firm thermoplastic gels with an increased level of gel strength. This is due to the unique branched polysaccharide galactose/mannose structure of cassia gum. Cassia is excellent at the formation of gels along with xanthan gums and other galactomannans thereby resulting in allowing lower hydrocolloid level formation in final formulations. Hence resulting in uniquely branched structure of polysaccharide mannose or galactose structure.

Translation of Cassia Gum in Diffrent Languages

| Catalan: | Goma cassia |

| Croatian: | Cassia guma |

| Danish: | Cassiagummi |

| Dutch: | Cassiapitmeel |

| Finnish: | Cassiakumi |

| French: | Gomme de cassia |

| German: | Cassiakernmehl |

| Polish: | Gumy cassia |

| Portuguese: | Goma de cassia |

| Romanian: | Guma de cassia |

| Slovenian: | Guma cassia |

| Spanish: | Goma cassia |

Physical and Chemical properties of cassia gum powder

- Color Yellow

- Oder Odorless

- Texture Free flowing fine powder

- Solubility Hot Water

- Gel Strength 500 Min

- Chrysophanic Acid 2 PPM Max.

| Particle size (Mesh) | 60 | 100 |

|---|---|---|

| Hot Viscosity 2 Hours (5% Sol. Brookfield RVT Viscometer 25°C, Spindle No. 4, 20 rpm) | 20,000 Cps to 60,000 Cps | 20,000 Cps to 60,000 Cps |

| Appearance | Yellow Powder | Yellow off-white Powder |

| Moisture | 12% Max. | 12% Max. |

| Protein | 5% Max. | 5% Max. |

| Ash | 1.0% Max. | 1.0% Max. |

| Acid Insoluble Residue(A.I.R.) | 3% Max. | 3% Max. |

| Gum Content (by difference) | 80% Min. | 80% Min. |

| Ph (1% Solution) | 5.5–7.0 | 5.5–7.0 |

| Fat | - | - |

| Specification | Cassia Gum 60 Mesh | Cassia Gum 100 Mesh |

Storage and Shelf Life

- Store in dry and fresh place, sheltered from light.

- Shelf life is 2 years from date of production.

Cassia Gum Powder Packaging

Packing will be done as per customer requirement like 25kg, 50lbs or 600 to 1000kg and 2000lbs. To know more about Cassia Gum applications

- HDPE Poly woven paper bag with inside liner

- Multi walled paper bags.

- Jumbo bags / Big bags